DynaPredict app for iPhone and iPad

DynaPredict is a data logger Bluetooth low energy with acceleration and temperature sensors designed to monitor the health of industrial machinery and perform spectral analysis (FFT). It is ideally used on machinery or equipment where vibration and temperature are relevant parameters for predictive maintenance. It periodically stores vibration and temperature data and, asynchronously, it also stores atypical data, i.e. data out of the normal pattern, or not provided in periodic measurements.

Monitored acceleration and temperature are instantly displayed on the screen of a smartphone or tablet via Bluetooth. DynaPredict stores the data in its internal memory. Once collected by the App, this data is transferred and centralized in the cloud, where it can be analyzed and shared. It can also perform a machine diagnosis via spectral analysis and time series.

The complete solution:

The complete solution includes the standalone DynaPredict device with acceleration and temperature sensors; the App for instant access to data for action and analysis at the shop floor, allowing spectral analysis and user identification and; the web software with data history for analysis and support of predictive maintenance decision making. The maintenance supervisor can configure the different levels of access and analyze the acquired data.

Where and how to use:

It is the ideal solution for the predictive or condition based maintenance of machines and equipment where parameters such as temperature and vibration are relevant, since it generates a diagnosis of the machine, identifying failures not yet noticeable and thus avoiding interruptions of the production process. The device can be used in many different industrial sectors.

Easy to use!

* DynaPredict is attached (glued or screwed) to the monitored equipment component;

* It is activated by a smartphone or tablet via Bluetooth low energy;

* It provides instant display of acceleration and temperature on the mobile device screen for immediate decision making.

* It generates advanced vibration analysis (spectral analysis);

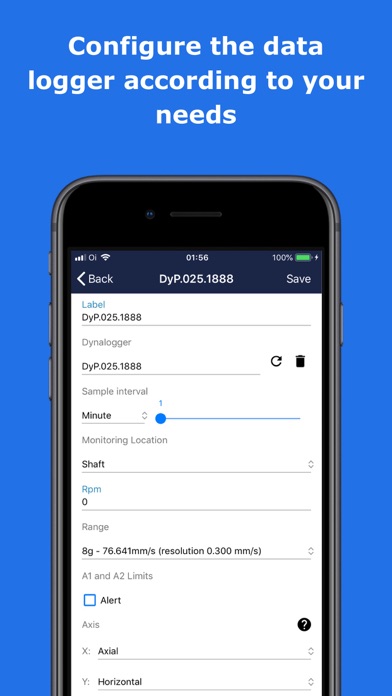

* It permits setting the alarm thresholds;

* It stores the monitored data and transfers it to the web system or local server, where it can be accessed and shared.

Benefits:

* It detects faults in early stages or not yet noticeable;

* It identifies fault evolution on monitored machines and components;

* Work is optimized allowing more time to data analysis and problem solving;

* It Improves employee safety and environment security;

* Improves the reliability and maintainability of the industry;

* Allows faster decision making due to access to instant information;

* It helps improve the use and management of the spare parts stock;

* It provides history of monitored data, photo record and activities performed. Furthermore, the monitored points are tracked.

* Tasks execution control: it allows users supervision in the different access levels.

Terms of Use: https://content.dynamox.net/en-termos-gerais-e-condicoes-de-uso

Privacy Policy: https://content.dynamox.net/privacy-notice